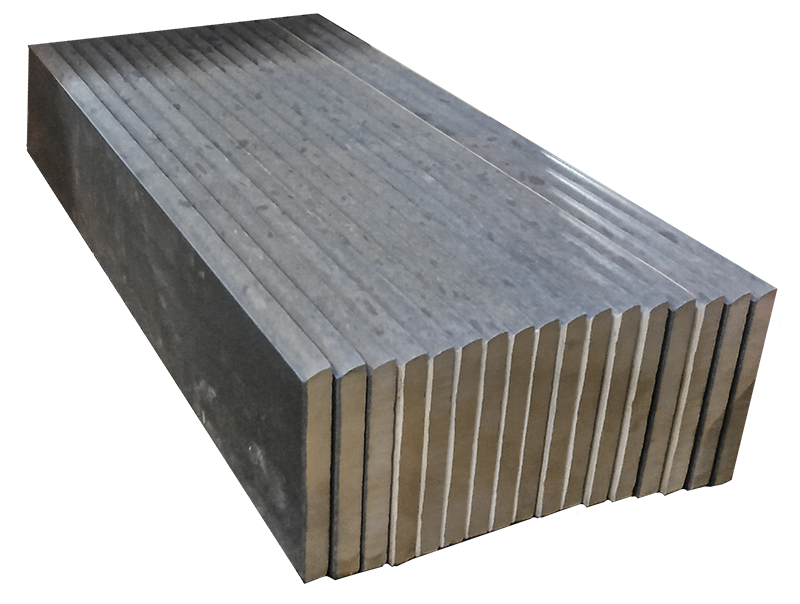

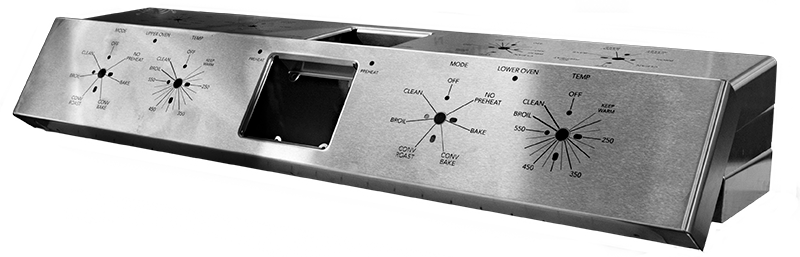

Despite the difficult period dictated by the pandemic, Ser-Tec continues the development of digital and screen printing solutions. The latest addition is the print line Hybrid materials such as ceramic, metal and glass: industrial printer "The Eagle 70 Hybrid" with belt loading and pre-heaters, mounted in line with the oven "FT Radiant" radiant, equipped with a metal mesh belt that guarantees greater capacity and less wear, especially with materials such as ceramics and metals.

The Eagle Hybrid 70, with single or double head, is equipped with sensors for the automatic detection of the incoming materials and their length, automatically adjusting the start and length of the print. Located just before the printer, the adjustable pre-heaters allow you to adapt the temperature to the different materials, significantly increasing the print adhesion. Furthermore, the IR lamp mounted on the side of the print head applies a first drying to the ink, which is then permanently fixed during the passage in the IR oven at the end of the line.

The modular construction of the "Hybrid" line allows it to be inserted into existing production lines and to be customized according to the materials and production needs of the customer.